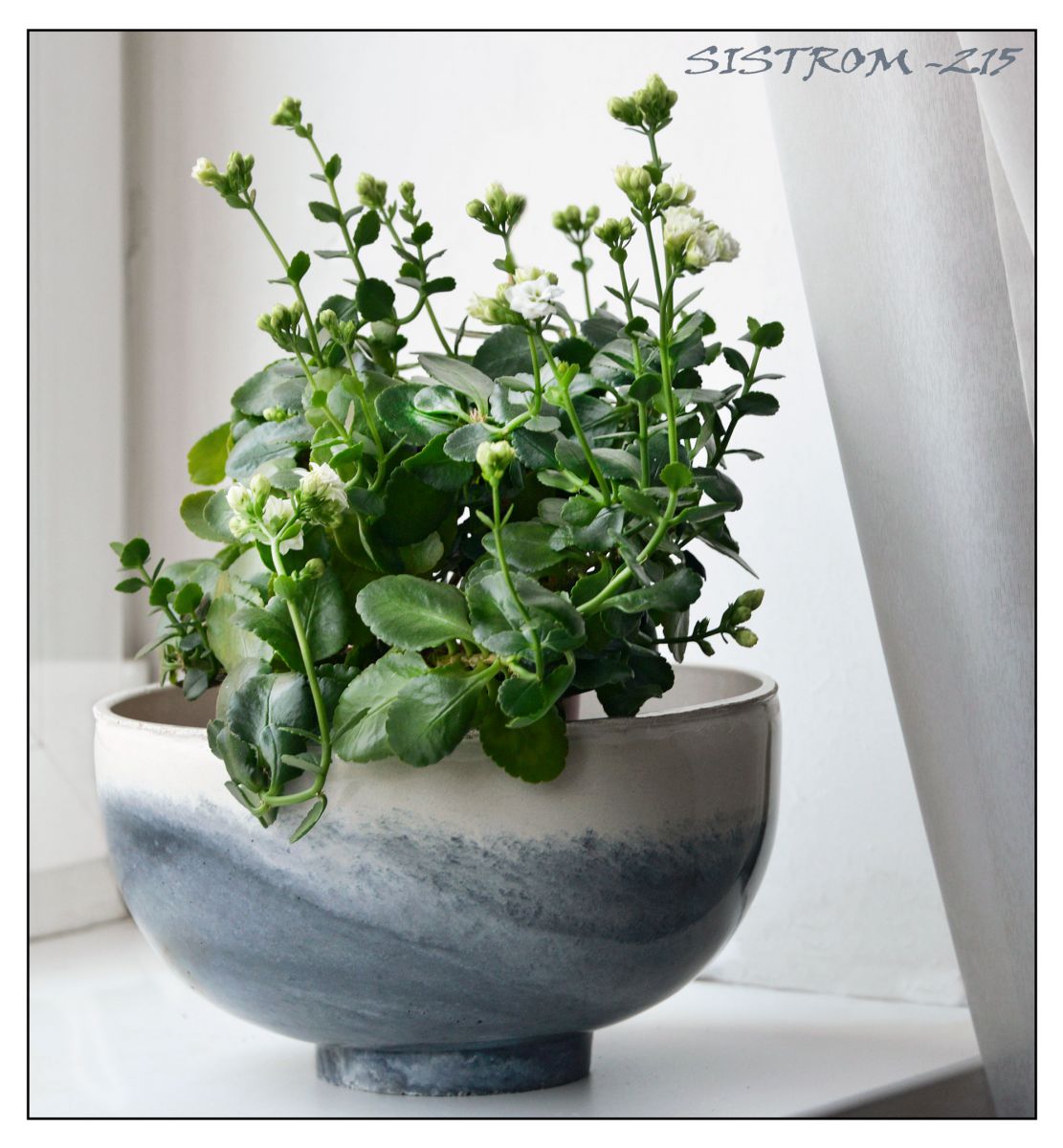

Marble from concrete

Annotation

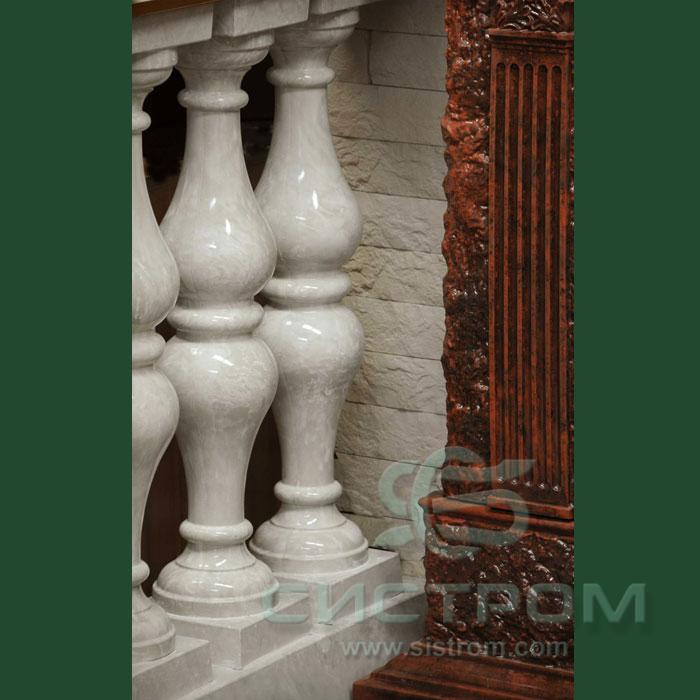

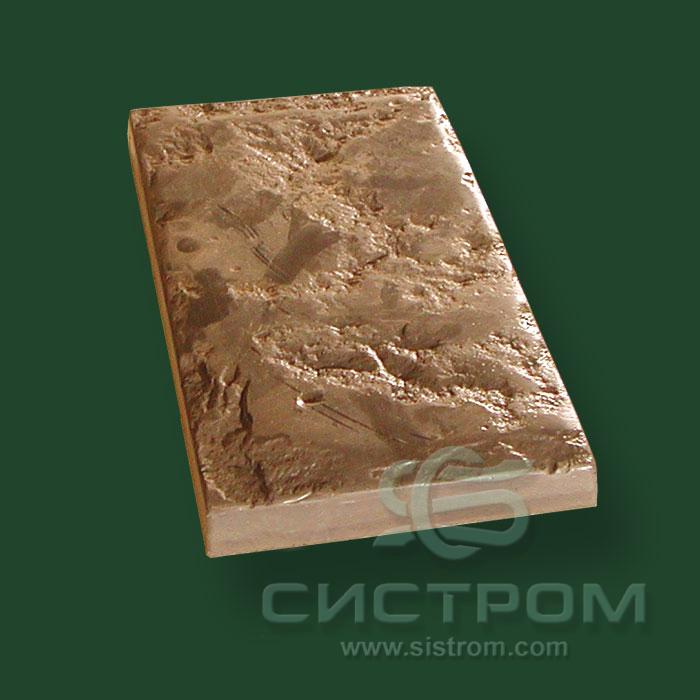

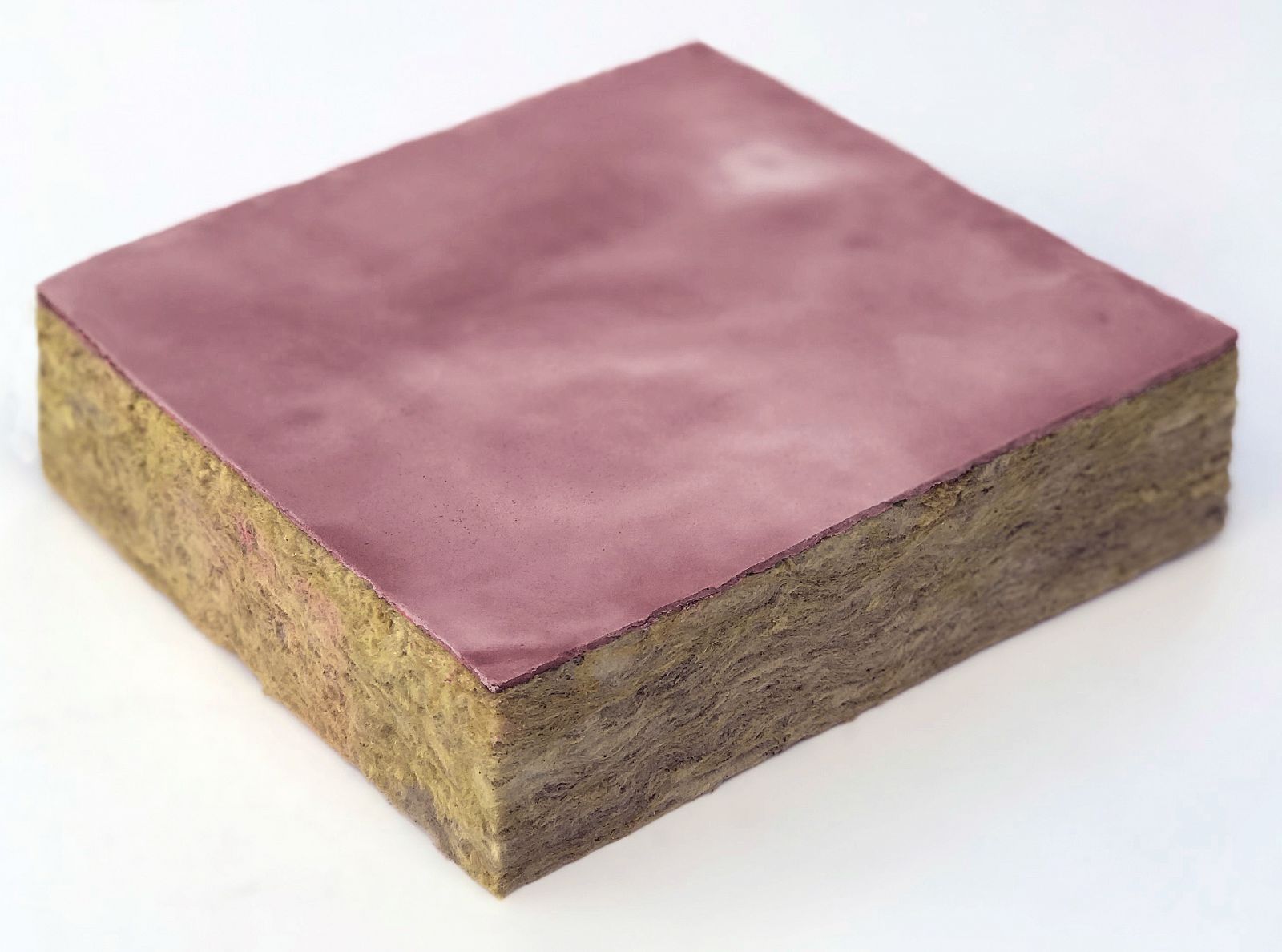

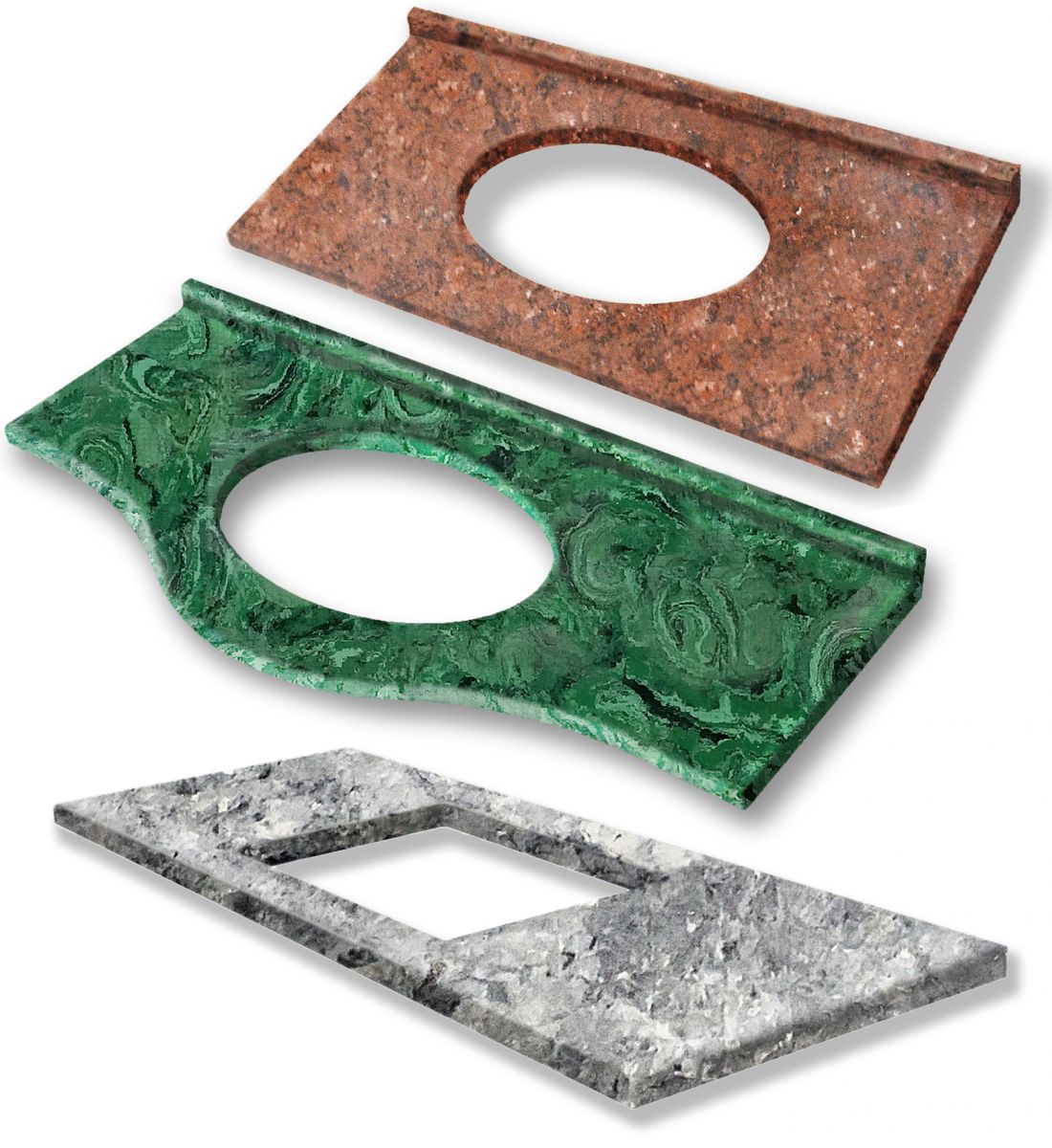

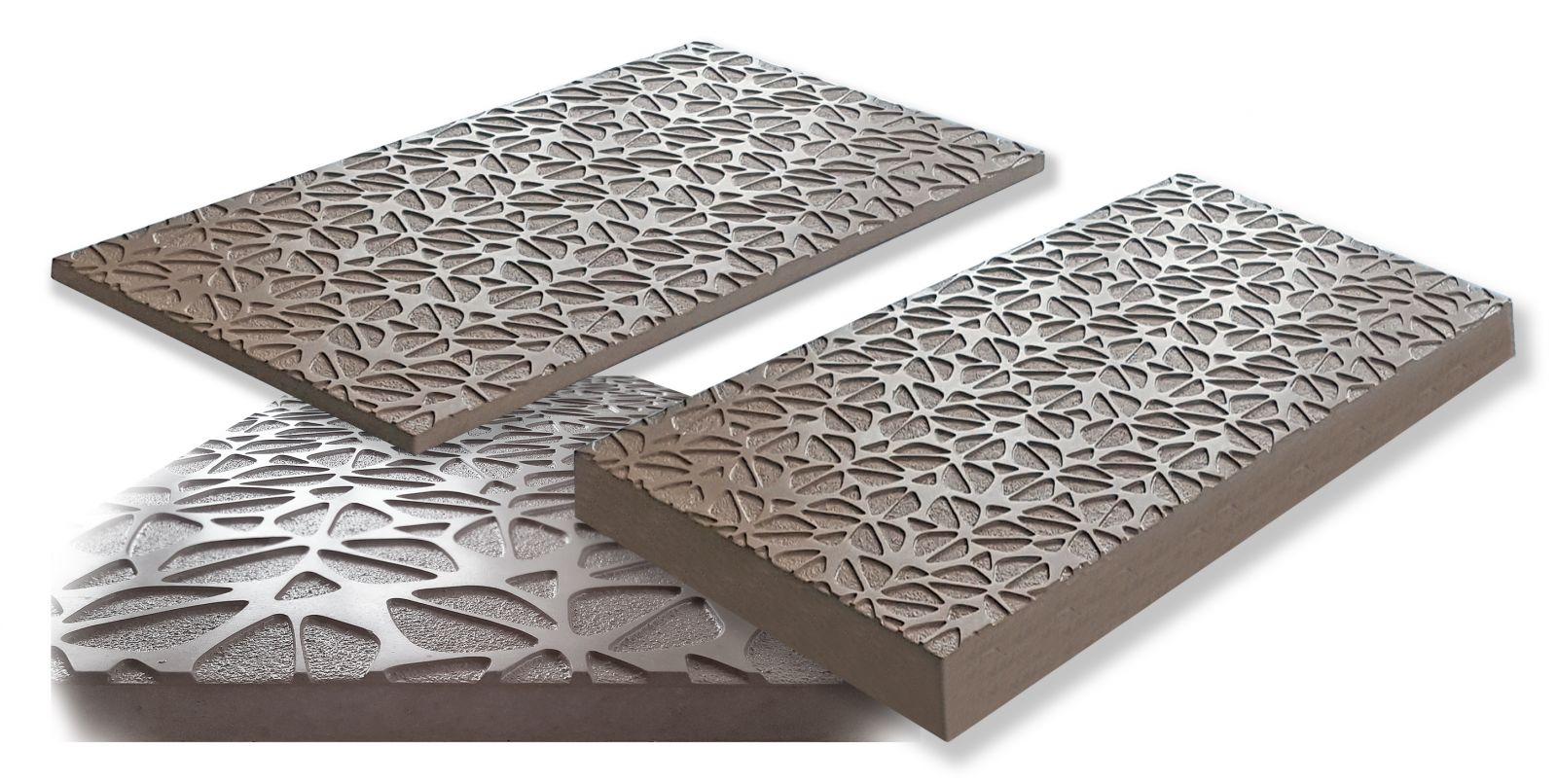

With the fast growing of the production of white cement and pigments any unevenly colored concrete produced under the traditional technology has been called “marble from concrete”. Of course in this case neither appearance nor technical characteristics could not be compared with the natural marble. However, nowadays there is a concrete which could not be distinguished from the natural marble even by professionals. The article presents the results of researches which served as a basement for the technology “marble from concrete” the innovative technology by SISTROM.

The background of the issue

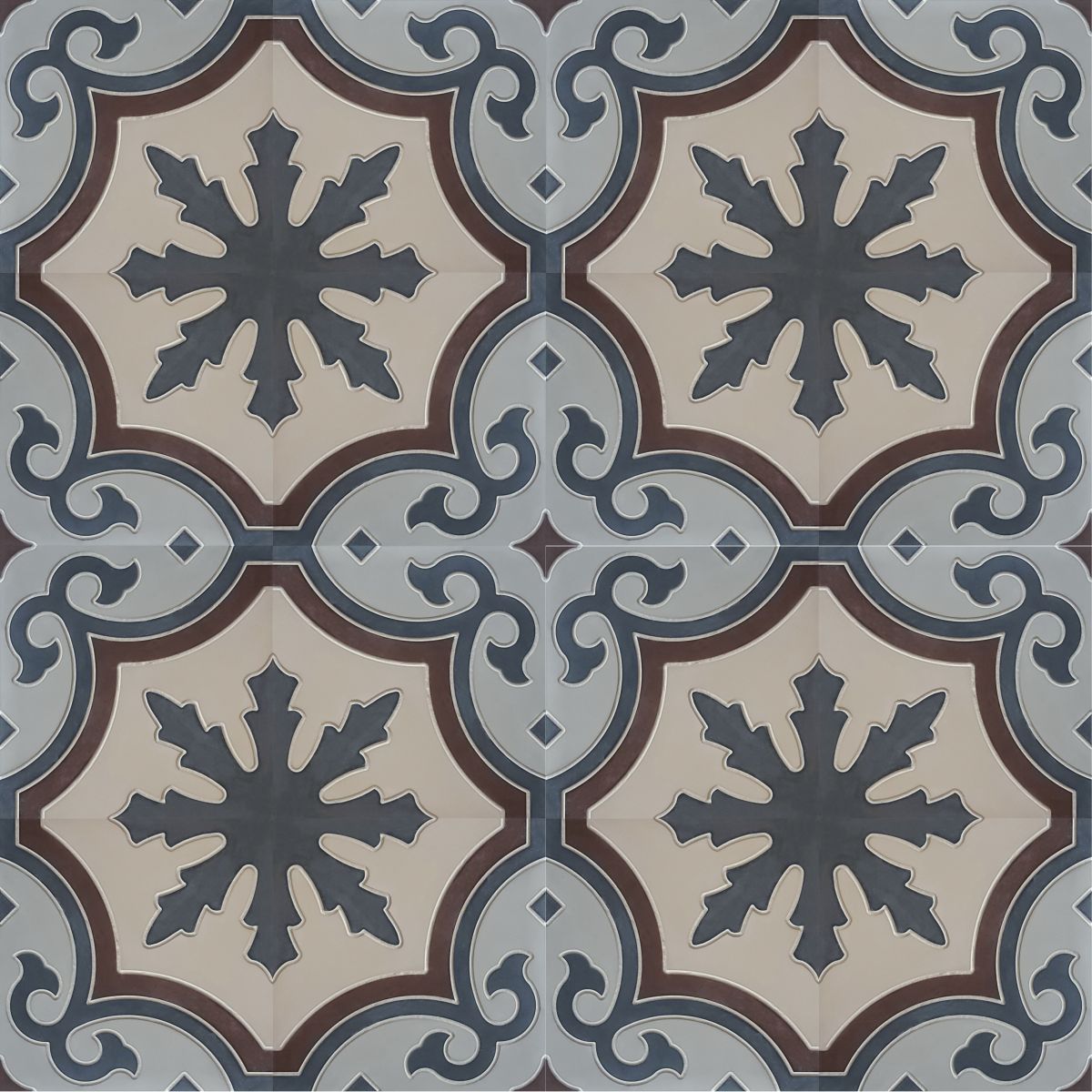

The idea of marbled concrete has begun from the painting the surface. This is done by artists and restorers. By painting the surface they try to imitate just a look of natural marble but not the technical characteristics. Such technologies do not guarantee durability and strength of products.

The other method is uneven distribution of the pigment throughout the volume of concrete. This leads to the decrease of strength in the parts with high concentration of pigment which is under the definition does not possess astringent properties. The pigments washed out forming cracks with further destruction of concrete.

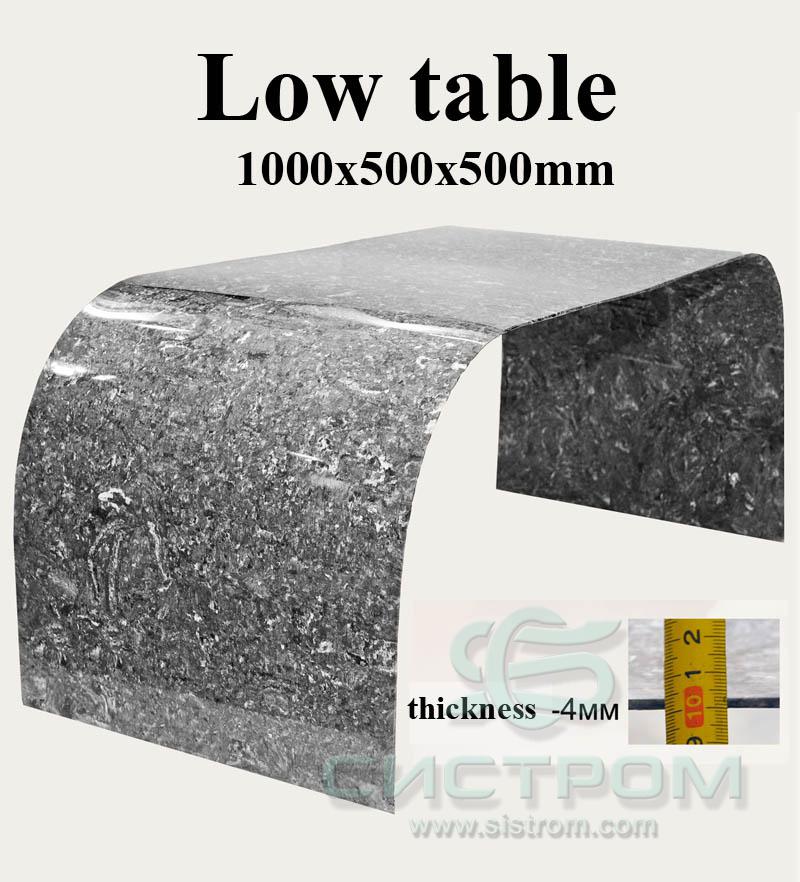

In 1991 SISTROM Company started to develop the new technology “Marble from concrete”. It was created an ultra-high strength SISTROM CONCRETE with 140 MPa strength and the technology for the production of marbled facing products based on SISTROM CONCRETE.

In 1998 the SISTROM Technology “marble from concrete” won a gold medal at the invention and innovation exhibition Brussels EUREKA’98.

The technology “marble from concrete”

At the first sight it is quite simple. There used just a cement, sand, water, pigments and additives. We use ordinary compulsory-type concrete mixer. They say: “Nothing new”. However the professional who learns concrete for years understands that it has been a revolution in concrete when he or she recognize just two parameters of SISTOM CONCRETE namely water cement ratio 0,2 and its high workability level. Briefly it could be characterized like “SISTROM had broken the sound barrier when achieved extremely low water-cement ratio”. More detailed it sounds like “it is known that 20% of water from the cement mass is a minimum amount that is required for the creation of cement stone. All water added beyond that amount loosens concrete, partly evaporates, creates directed porosity and reduces technical parameters. For mixing the standard concrete they add 2-3 times more water than it is needed for the hydration process – from 40 to 60% from the cement mass. That is why SISTROM CONCRETE with water-cement ratio 0,2 gets phenomenal strength 100MPa on the 1’st day.

.jpg)

.jpg)

(1).jpg)

.jpg)