Plastic moulds for concrete

Plastic moulds for the concrete

Traditionally in the process of production of concrete items wood or metal moulds are used. However, these materials have a high adhesion that leads to some difficulties while moulds removal. In order to remove concrete from a mould easily, metal surfaces are usually lubricated with special oil. This oil demolishes the top layer of concrete, preventing its hardening in the place of contact with the metal. However, after mould removal concrete’s surface has sleazy appearance and needs additional treatment. The same as to wooden moulds. It was necessary to find a material with no adhesion to concrete. It is known that some polymeric materials have such properties. At 90’s SISTROM Company was the first to develop and bring to market plastic moulds for the concrete. It became possible due to production of new plastics, so called polymers, having high physical and mechanical properties.

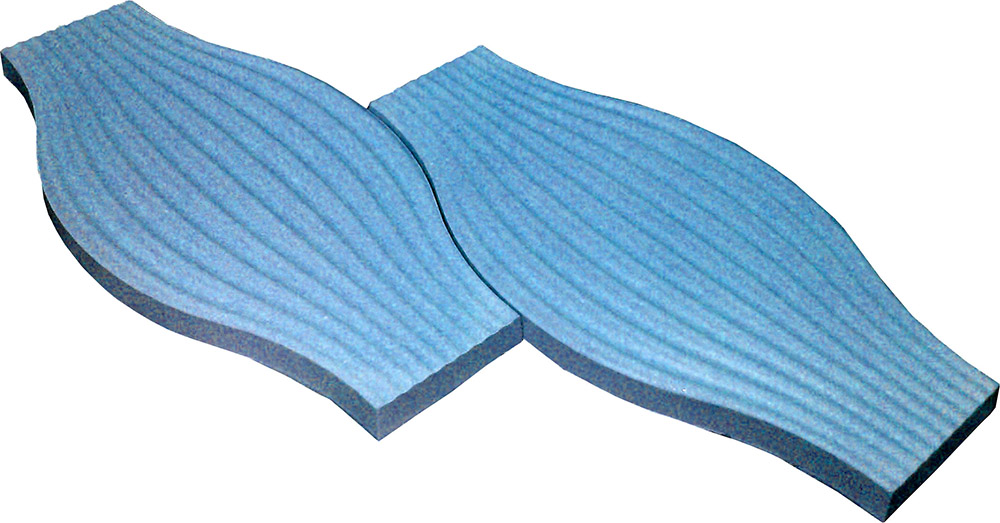

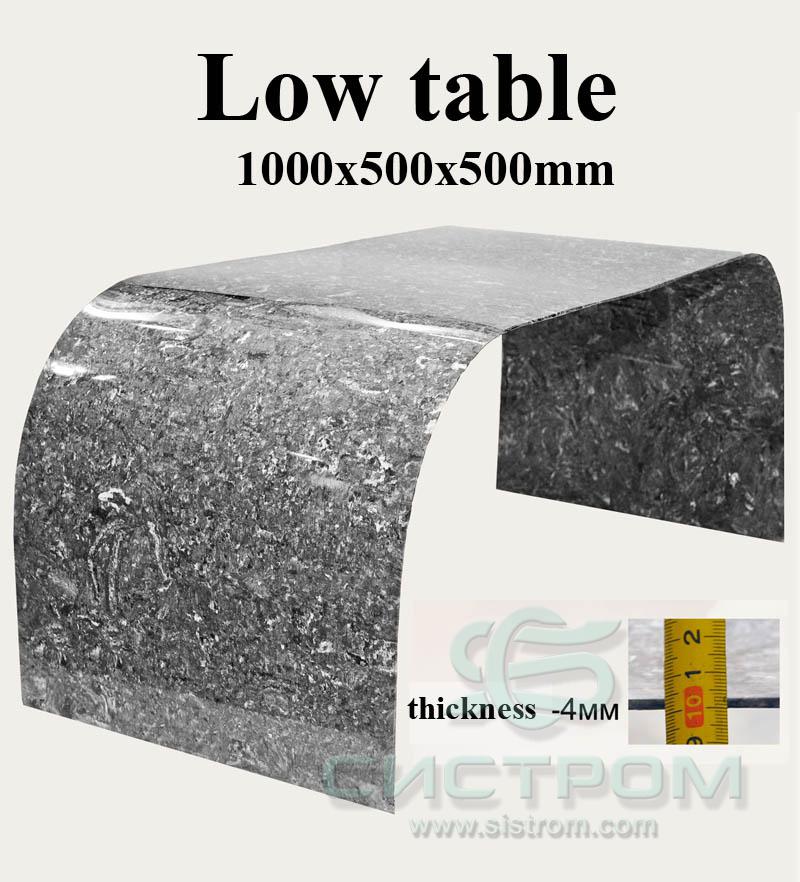

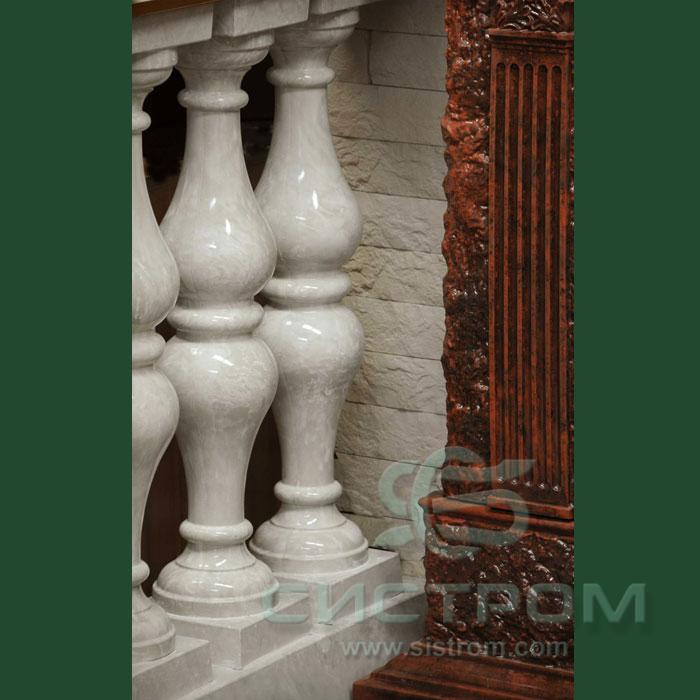

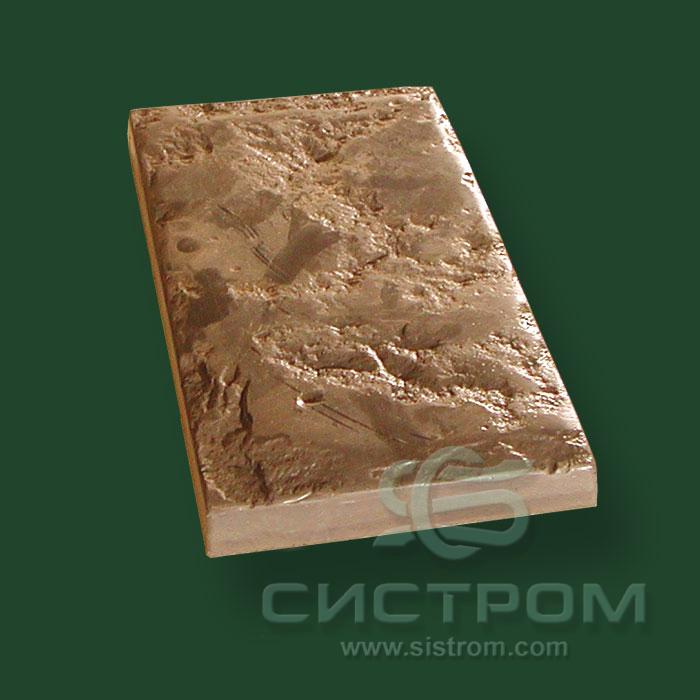

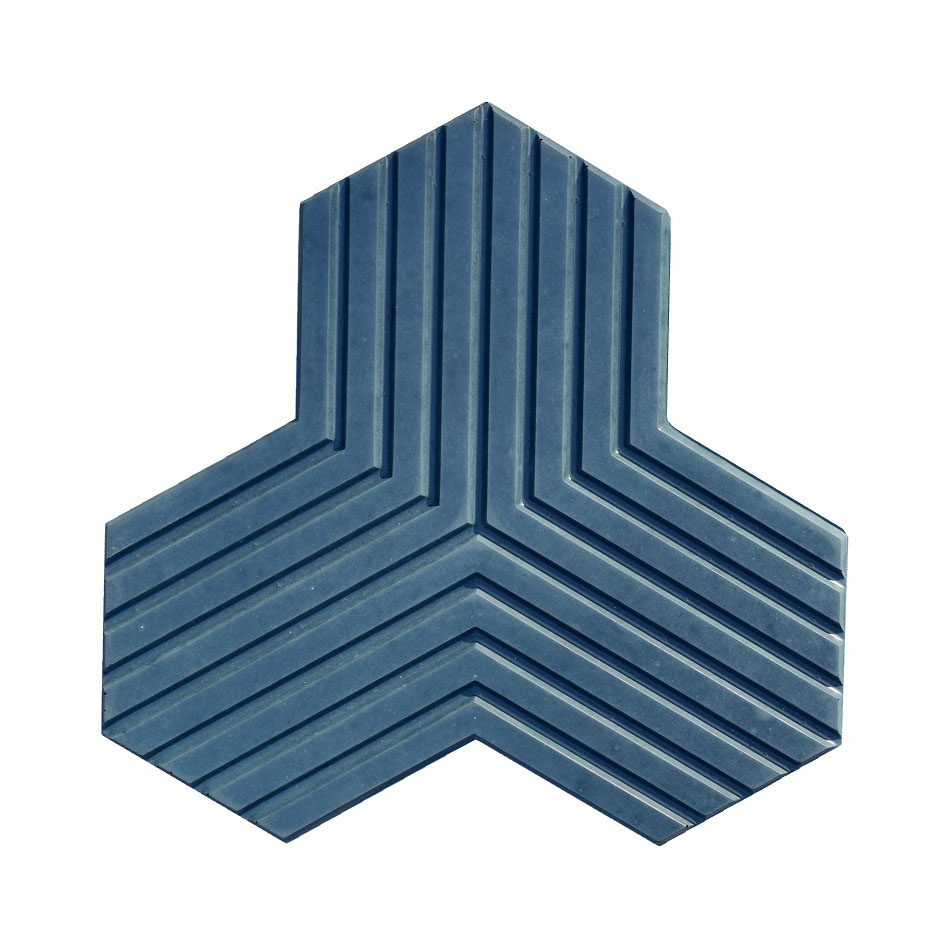

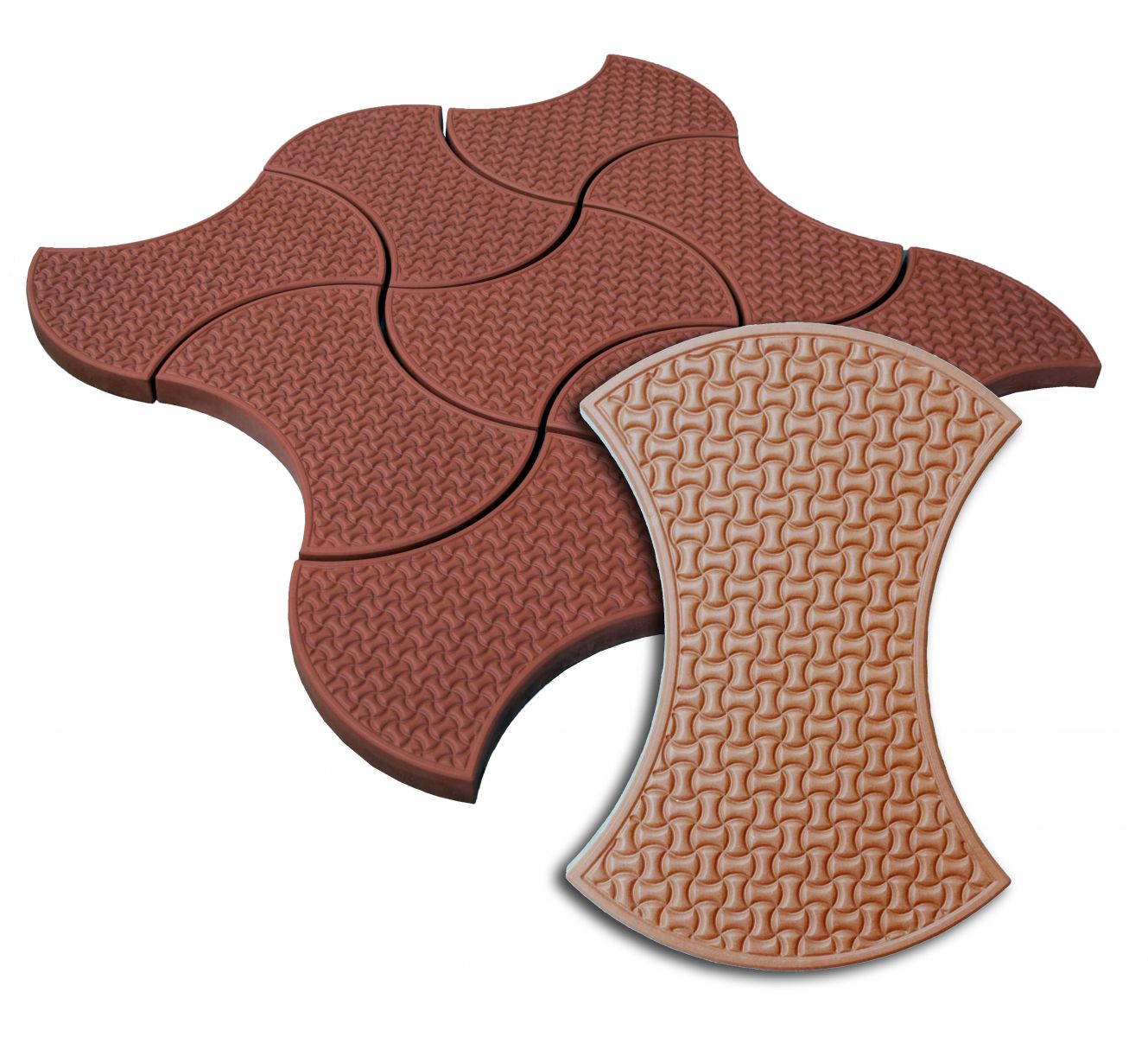

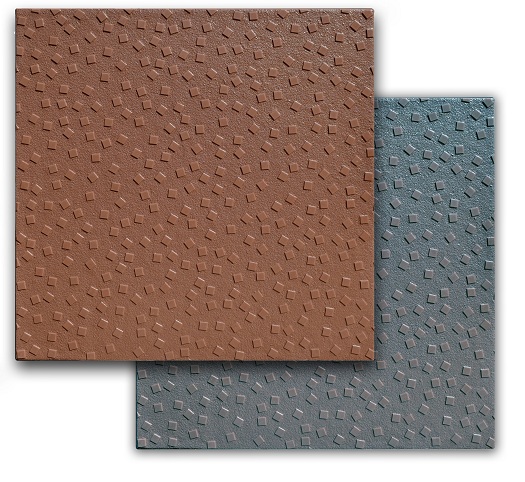

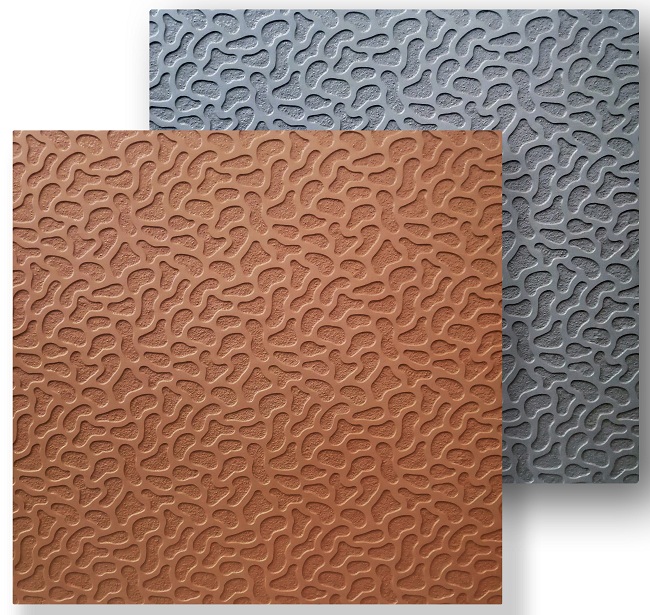

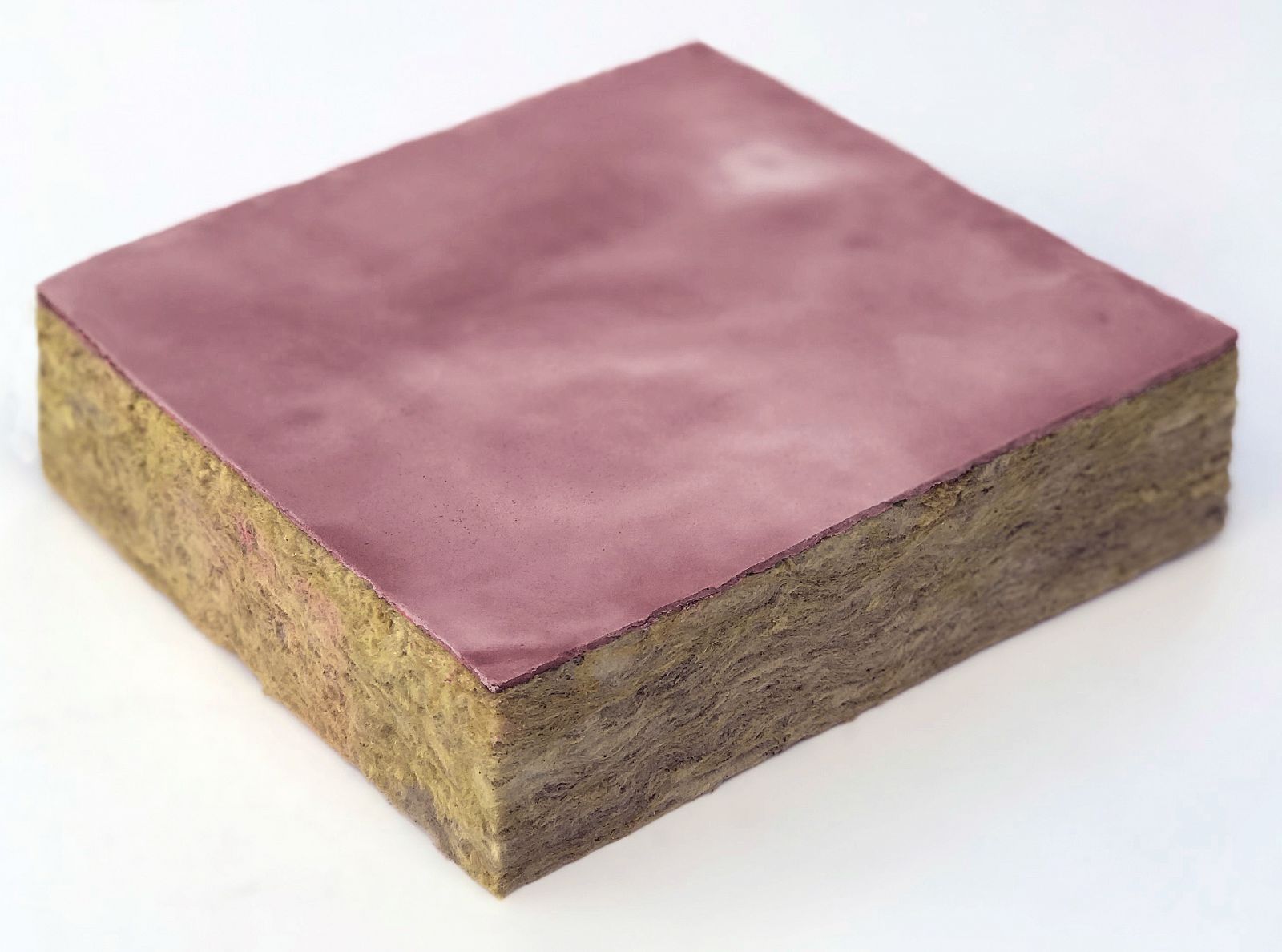

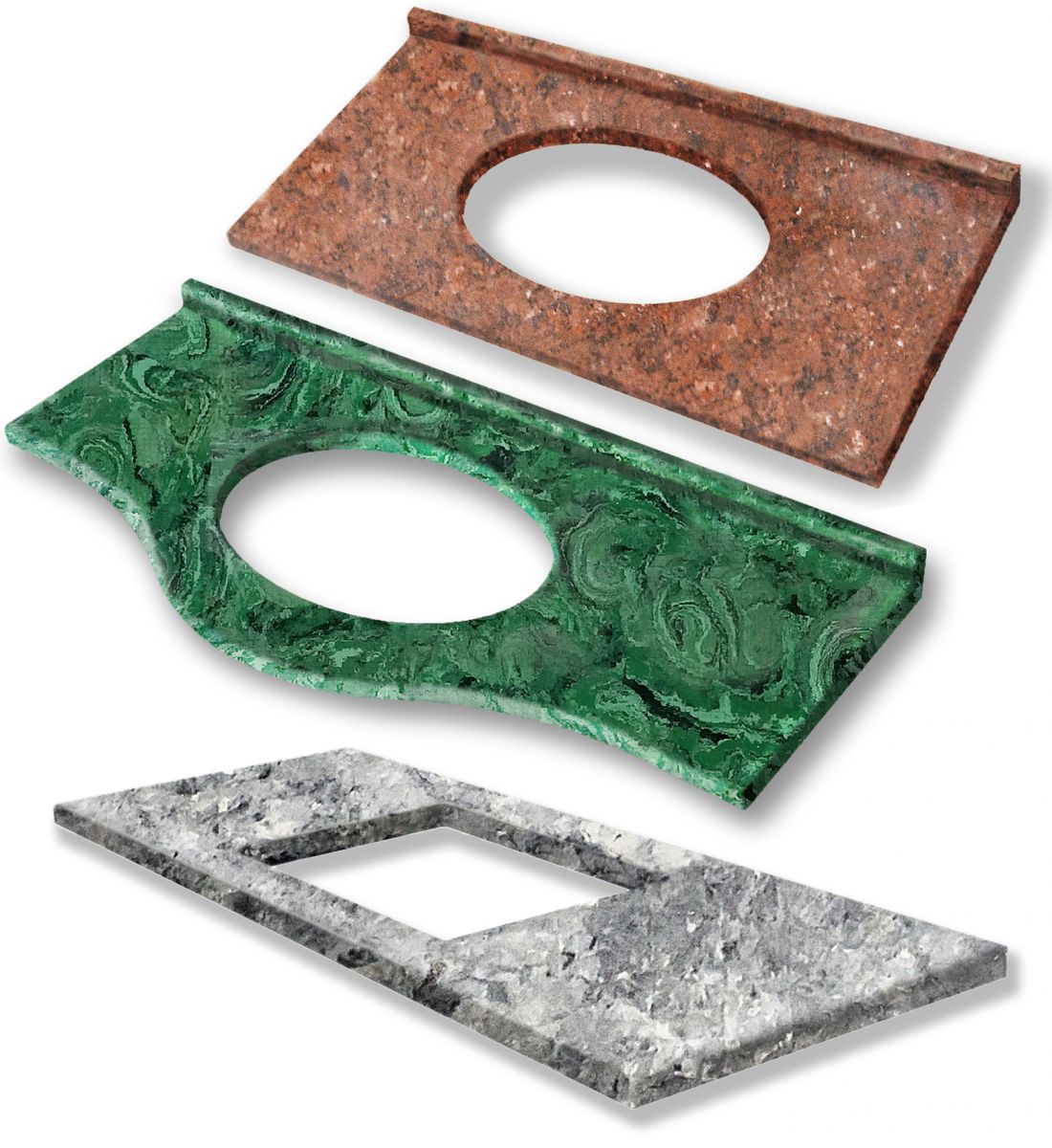

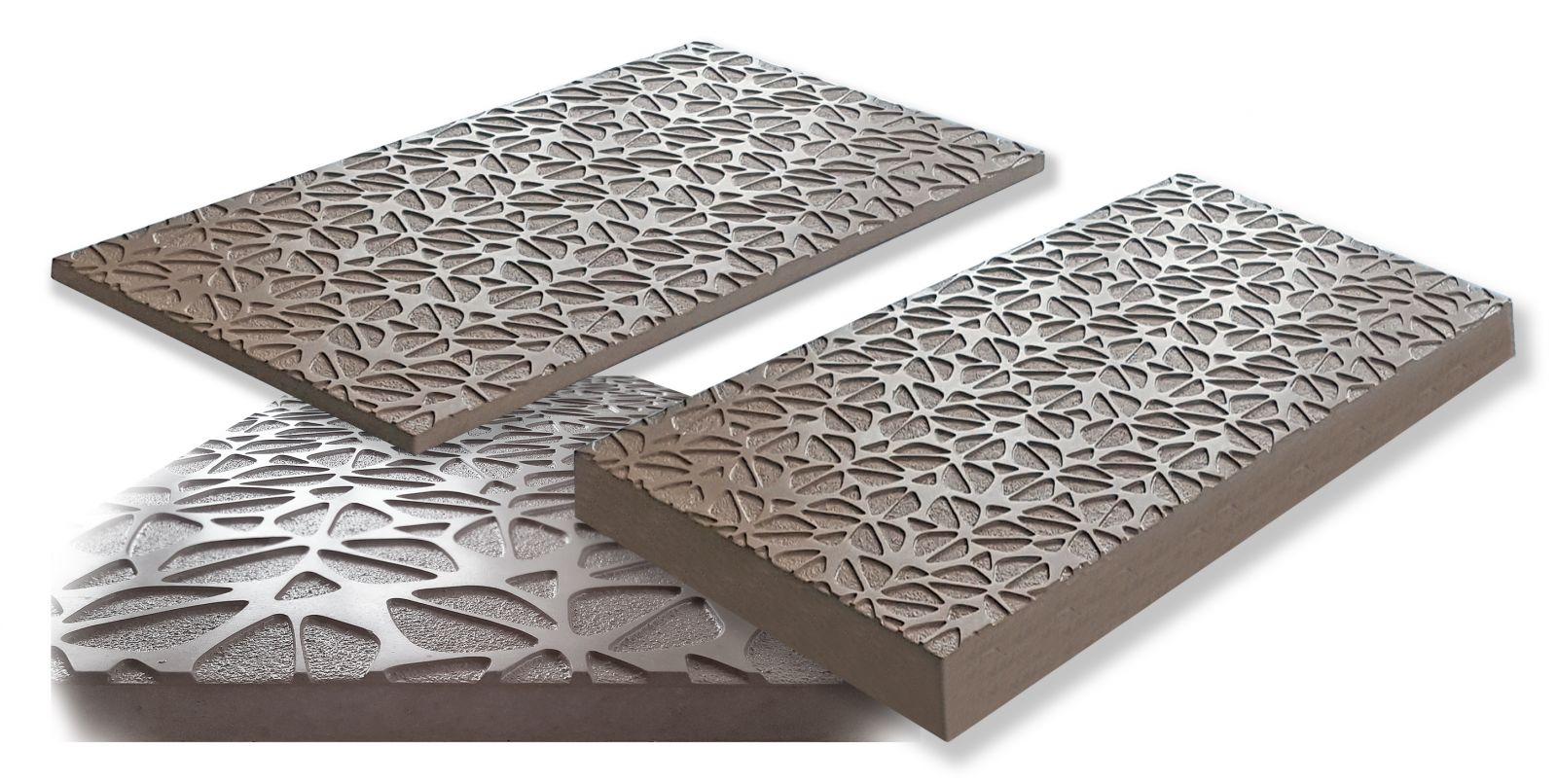

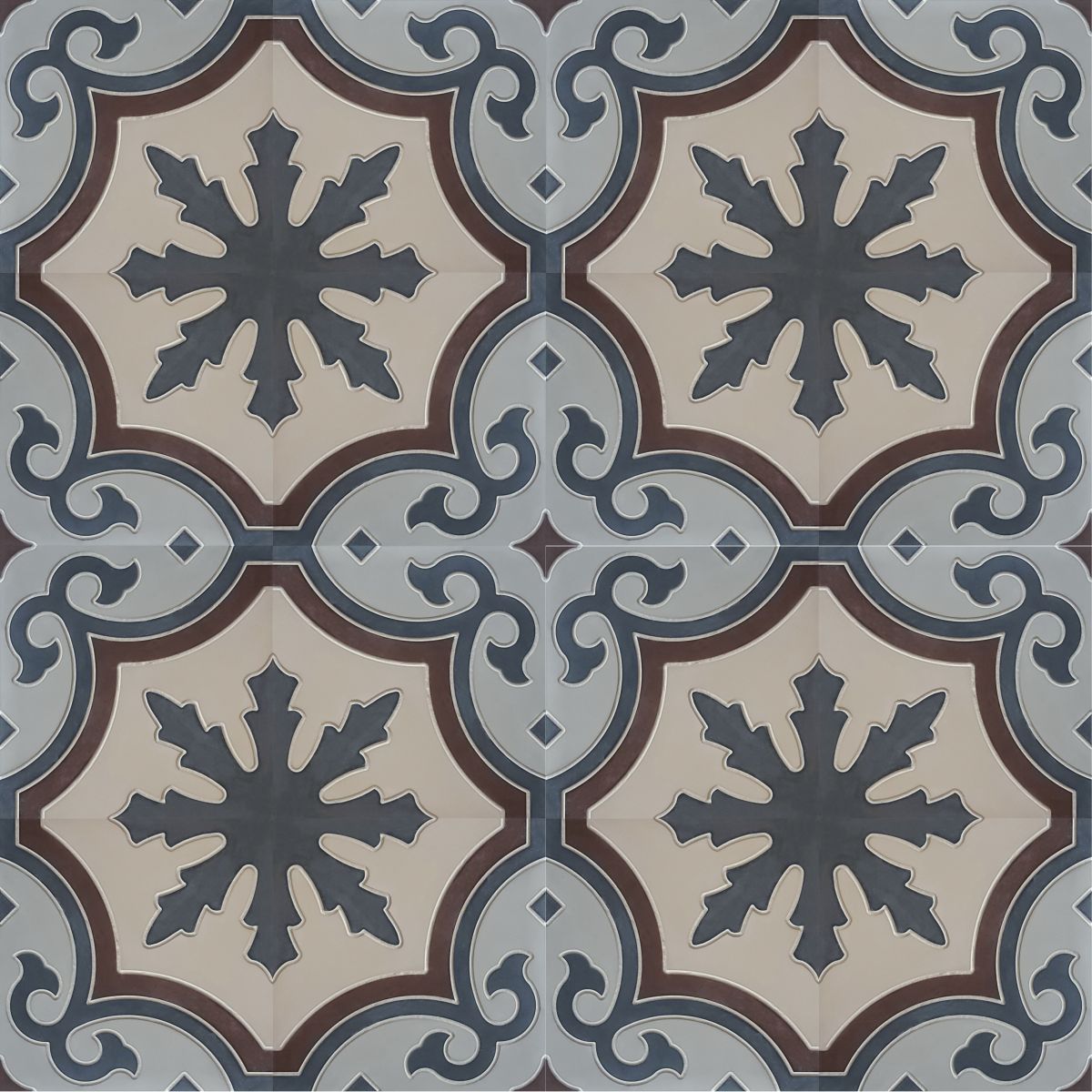

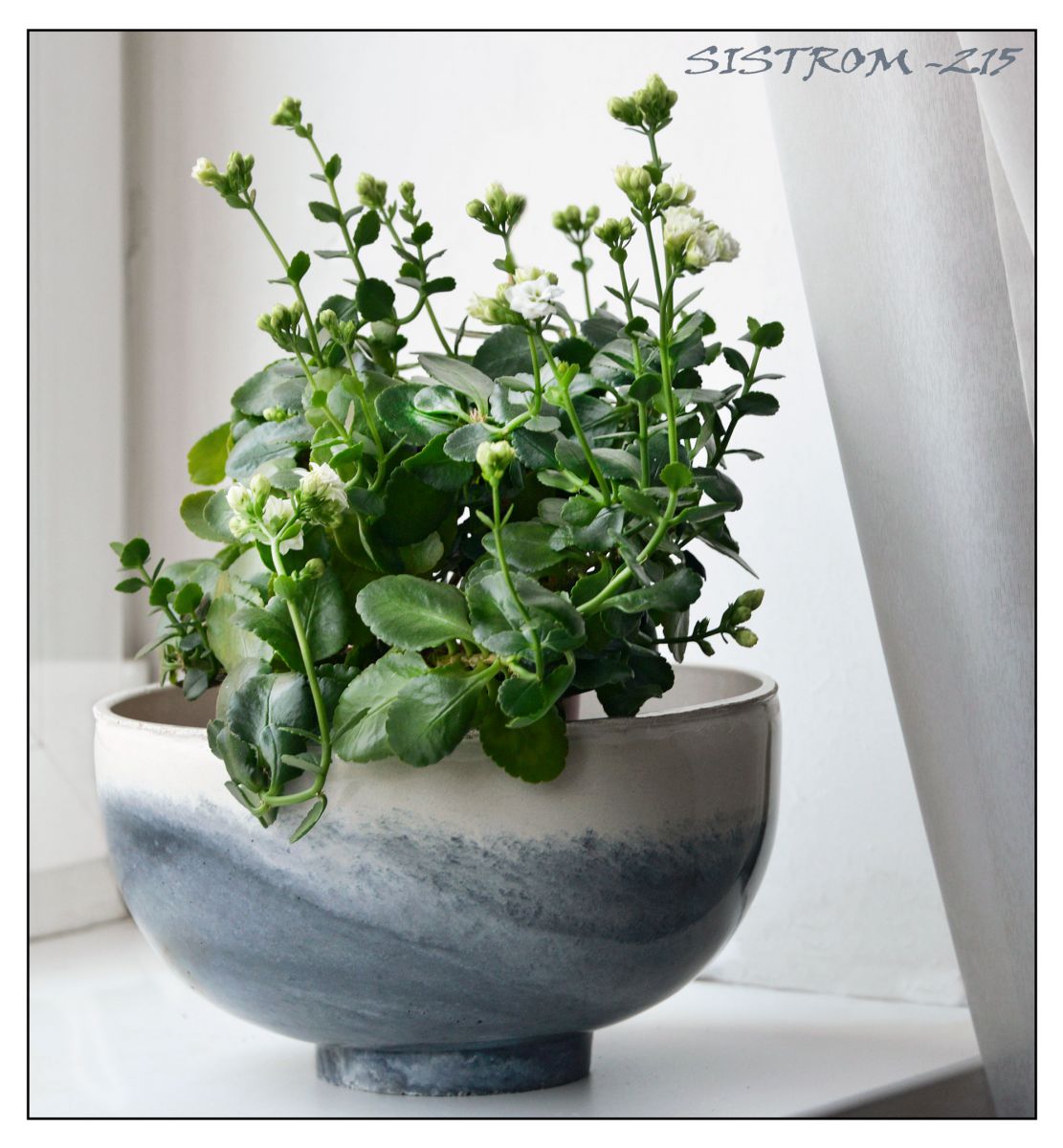

Plastic moulds SISTROM don’t need special lubrication and are firm enough to provide precise dimensions of concrete products. In the process of concrete mix moulding facedown, the most firm top layer appears due to redistribution of the most solid and heavy mix components contacting polymer mould. Later on, while using concrete products, exactly this working layer undergoes primary load, provides high wearability and shock strength. It is possible to create different kinds of surfaces imitating crude stone, glazed and even mirror surface. Plastic moulds for the concrete became a part of SISTROM technology “Marble from concrete”.

In 1998 the SISTROM technology was awarded a gold medal at Brussels’s World Exhibition on inventions, research and new technologies. The unique kind of high-strength fast-hardening concrete was elaborated for this technology. It’s compressive strength at first 24 hours of normal hardening amounts to 60 MPa, and 100 MPa in 14 days. Concrete’s colouring is made by weight as a natural stone. Water absorption less than 2-3% provides high frost resistance over F500. SISTROM’s plastic moulds show high quality and durability. Product range exceeds 500 kinds and dimension-types. However, customers have a possibility to order moulds according to their design.

.jpg)

.jpg)

(1).jpg)

.jpg)